11.4 LED LUMINAIRES

11.4.1 DOWNLIGHT TYPE LED LUMINARES

11.4.1.1. The luminaires shall be of type approved by Suruhanjaya Tenaga (ST).

11.4.1.2. The luminaires shall comply with the relevant Malaysian Standards or IEC Standards and other relevant standards in terms of safety and performance criteria. The luminaires shall comply to MS IEC 60598 Series, IES LM-79-08, IES LM-80-08, MS 62722, MS IEC 62031, IEC 62471, IEC 61547, M S IEC 61000-3-2 and BS EN 55015 / CISPR 15.

11.4.1.3. The luminaires shall be designed and constructed that it is capable of providing the service for which is intended. It shall be manufactured under “Lighting Class LED” and shall be commercially available.

11.4.1.4. The LED luminaires shall be new and complete with LED control gear (LED driver), thermal management unit, surge and overvoltage protection and suitable for supply voltage of 230 V, +10%, -6% at 50 Hz. The LED luminaire shall consist of two separate components comprising of LED control gear and optical system.

11.4.1.4.1 The construction of the luminaires shall be of either two separate housing / compartments or integrated.

11.4.1.4.2 The luminaire shall be shined downwards to provide uniform light distribution and it shall have adequate heat sink for heat dissipation / thermal management.

11.4.1.4.3 All components of the luminaires shall operate well within the ratings with due consideration for the local conditions (high humidity of 95% RH and ambient temperature of 35°C)

11.4.1.4.4 Interchangeability of consumable components is preferred for maintenance purposes.

11.4.1.4.5 The luminaires in mode of operation shall not produce voltage disturbance / fluctuation to the electrical supply system.

11.4.1.4.6 The housing of the LED control gear and opt ical system shall be of sound and rigid construction suitable for suspended installation. A means of connecting the flexible GI conduit to the lamp control gear / luminaires shall be provided.

11.4.1.4.7 Material used for the construction of the luminaires and its component shall be recyclable.

11.4.1.5.1 Harmonics distortion shall be within the limits in accordance with MS IEC 61000-3-2. However, total harmonics distortion shall be less than 20%. The LED control gear shall operate and maintain consistent light output over voltage variation from +10% to -6% of the rated voltage and power factor of not less than 0.9 lagging.

11.4.1.5.2 The LED control gear shall be able to withstand short circuit current, overload, over voltage, under voltage and over temperature.

11.4.1.5.3 The optical system shall incorporate one piece full bowl reflector where applicable and high power LED or LED module of required wattage and shall comply to MS IEC 62031 and IEC 62471. The luminaire shall continue to operate safely even though there is failure of a partial number of LEDs / LED. The LEDs / LED module lumen output shall not be depreciated to below 70% of the original output during the liability / warranty / contract period (whichever is applicable). The initial luminous flux shall not be less than 90% of the rated luminous flux.

11.4.1.5.4 There shall be no flickering of the light source in mode of operation and when it reaches its end of life.

11.4.1.5.5 The LED / LED module shall not be driven more than the rated drive current.

11.4.1.6. The optical system support shall be made from mild steel / die cast aluminum w i t h minimum thickness of 1 . 3 m m . The ring shall be made from die-cast aluminum with minimum thickness of 1.3 mm. The support and ring shall be coated with electrostatic powder. The clip shall be made from stainless steel.

11.4.1.6.1 The optical system shall comprise of optical lens reflector and glass diffuser (if applicable). It shall give good even light distribution with minimal glare in both the axial and transverse planes.

11.4.1.6.2 When applicable, the reflector shall be made of high purity anodized

11.4.1.6.3 Photometric data for the luminaires shall be made available and submitted. The required photometric data for the luminaires shall be Polar Curve, Utilization Factor, Luminance Distribution Table, Downward Light Output Ratio, Upward Light Output Ratio, Light Output Ratio and Spacing to Mounting Height Ratio.

11.4.1.7 Connection cable shall be terminated in a termination block marked L and N for connection of the incoming wires. For Class 1 luminaries a brass direct pressure type earth teminal shall be provided in the Led driver system near the termination block for earth connection . This terminal shall be clearly marked with the started earth terminal symbol.

1.4.1.7.1 For seperated optical and LED control gear , electrical connection of the led control gear and optical system shall be through a plug and socket (i.e male / female connection unit) it shall be made from no flammable meterial and shall be rated at 10A .It shall comply to MS IEC 60838-2-2.

11.4.1.7.2 Heat Resistant (HR) 105˚C cable shall be used to connect the optical system and LED c o n t r o l g e a r and shall be of stranded type. It shall not be more than 300 mm long. The cable shall be enclosed in a cable sleeve HR 105˚C

11.4.1.7.3 Wiring shall be done in a neat way to avoid contact with heat producing components. A means of clamping the electrical cable shall be provided. The cable clamp arrangement shall not damage the insulation of the cables.

11.4.1.7.4 Where optical and control gear system are not integrated, both the optical and control gear system shall be provided with hooks or other suitable means for hanging purposes.

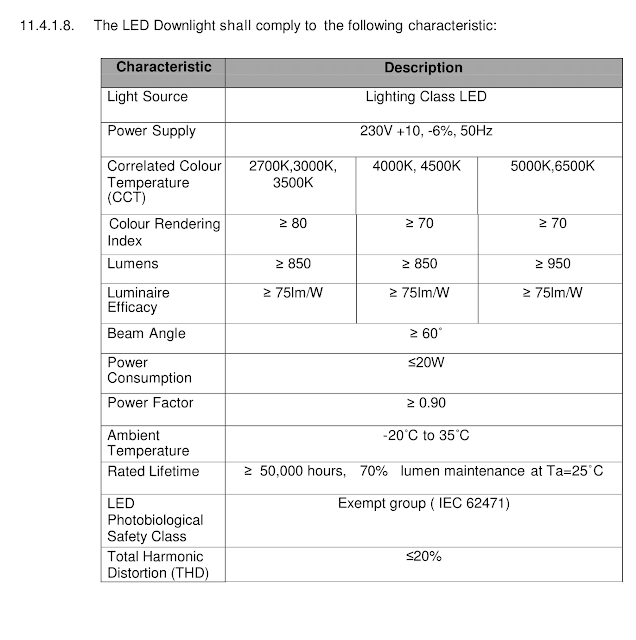

Table 11.4.1: Characteristics of LED Downlight

11.4.1.9. The manufacturer shall provide a minimum 5 years period warranty certificate as stated in the defect liability / warranty / contract period (whichever is applicable) for the complete luminaire to guarantee the long life expectancy and maintenance-free luminaire. Warranty declaration shall be filled and signed by manufacturer. Failure in the functioning and operation of the LED luminaire within the warranty period will result in the replacement of the whole luminaire or required components by the manufacturer at no cost to the JKR.

11.4.1.10. Illuminance test shall be carried out every six (6) months during defect liability / warranty / contract period (whichever is applicable) to ensure the performance of the installed system conform to the design requirement as per JKR specifications. This test shall also confirm the lumen maintenance of the luminaire.

11.4.1.10.1 The luminaire manufacturer shall provide calibrated illuminance meter and have the capacity and competency to carry out the illuminance test during the testing of the installed lighting system.

11.4.1.11. Conformity with Standards The LED luminaire shall comply with and be tested to the relevant latest edition of Malaysia Standard or other relevant international standard as below: